Mining automation is reshaping the mining industry in unprecedented ways. This process leverages advanced technologies to streamline operations and enhance productivity. With its integration, mining sites are becoming safer and more efficient.

This innovation leads to a significant reduction in human labor. However, it brings concerns about job displacement. The industry must find a balance between automation and human roles. Many companies are investing heavily in automation systems, yet the transition can be challenging.

The potential for increased output is enticing. Automation enables real-time data analysis and improved resource management. Nevertheless, there are limitations in adapting to new technologies. Embracing mining automation carries risks, but also opportunities. The future of mining may depend on how well we navigate this transformation.

Mining automation refers to the use of technology to operate mining processes with minimal human intervention. This involves various technologies such as robotics, artificial intelligence, and machine learning. Key components include automated drilling systems and autonomous vehicles. These implementations can increase safety and efficiency, but they also raise questions about job displacement.

Automated drilling systems enhance precision and reduce human error. They allow for drilling at deeper depths, which can lead to better resource extraction. Autonomous vehicles transport materials and personnel, minimizing risk in hazardous areas. These advancements promise increased productivity but may require additional training for workers to adapt to new roles.

While mining automation offers significant benefits, it also poses challenges. Workers must reassess their skills in a rapidly changing environment. Concerns about reliance on technology persist, as unexpected failures can disrupt operations. Therefore, while automation is transforming the industry, it also demands careful consideration of its broader impact on the workforce and operations.

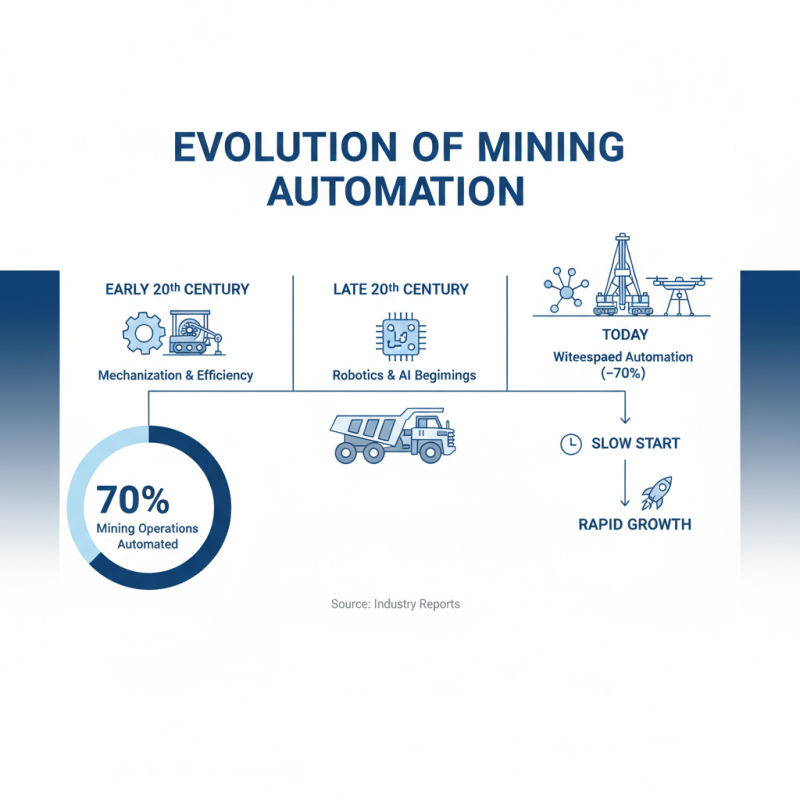

Mining automation has evolved significantly over the years. The roots of automation can be traced back to the 20th century. Early efforts focused on mechanization to improve efficiency and reduce human labor. According to industry reports, around 70% of mining operations now employ some form of automation technology. This shift began slowly but gained momentum with advancements in robotics and AI.

The integration of automated systems has not been without challenges. Many companies faced difficulties in retraining their workforce. The risk of job displacement raised concerns within communities reliant on traditional mining jobs. A study highlighted that while automation boosts productivity by up to 30%, it requires careful implementation. Balancing technological advancements with social responsibility remains a critical issue.

Despite its challenges, mining automation drives transformation. Sensors and robotics enhance safety by performing dangerous tasks. Reports indicate a significant reduction in accidents due to automation. Moreover, efficient resource extraction leads to better environmental outcomes. As the industry moves forward, stakeholders must address the implications of automation while embracing its advantages.

Mining automation leverages advanced technology to optimize operations. Innovations like autonomous vehicles, drones, and AI-driven analytics are revolutionizing the sector. A report by McKinsey shows that automation can boost productivity by up to 30%. However, not all companies are ready to embrace these changes.

Many mining environments are still deeply reliant on manual labor. This reliance can lead to inefficiencies and increased safety risks. Industry experts note that about 60% of mining workers may face job transformations due to automation. The challenge lies in reskilling the workforce for new roles in this evolving landscape.

**Tip:** Invest in training programs early to equip employees with necessary skills. Integration of automation should be gradual. Slowly adapting technology can help mitigate disruption. Striking a balance between innovation and human resources is crucial for a successful transition.

| Dimension | Description | Impact |

|---|---|---|

| Robotics | Automated machinery for drilling, hauling, and transporting materials. | Increases efficiency, reduces human error, and lowers operational costs. |

| Data Analytics | Utilization of big data to analyze geological data and production metrics. | Enhances decision-making and predictive maintenance. |

| Artificial Intelligence | AI systems to optimize operations and resource allocation. | Increases productivity and safety by minimizing risks. |

| Remote Monitoring | Real-time monitoring of equipment and operations from distant locations. | Improves operational oversight and safety controls. |

| Drones | Unmanned aerial vehicles for surveying and mapping. | Reduces costs and time for land assessments and monitoring. |

Mining automation is reshaping the industry, primarily enhancing efficiency and safety for workers. A report from the International Council on Mining and Metals highlights that automation can improve operational efficiency by up to 40%. This increase allows companies to extract more resources at a fraction of the labor cost. However, the transition to automated systems can pose challenges. Workers must adapt to new technologies, and companies need to invest heavily in training and infrastructure.

Safety is another significant benefit of mining automation. According to the U.S. Bureau of Mines, the implementation of automated systems can reduce workplace accidents by 30%. Automated vehicles and machinery can operate in hazardous conditions without putting human lives at risk. Nevertheless, relying on technology also raises concerns. Failures in automated systems could lead to severe consequences. Continuous monitoring and maintenance are essential to mitigate risks.

Despite these advancements, not all mining operations fully embrace automation. Some sites lag due to high initial costs or technical difficulties. A survey from a mining industry analyst reveals that 25% of companies are still hesitant about significant investments in automation. Balancing the advantages with potential drawbacks is crucial for future growth in the mining sector.

Mining automation is a promising yet challenging frontier in the industry. Reports highlight that the global mining automation market could reach $3.29 billion by 2025, reflecting a compound annual growth rate of 7.6%. However, this transformation isn't without obstacles. Integrating advanced technologies requires significant investment and can lead to workforce displacement. Industry professionals must deal with resistance to change and the need for upskilling workers.

To navigate these challenges, companies should prioritize training programs that prepare the workforce for new roles. Emphasizing safety and adaptability can ease the transition. As automation systems advance, ensuring that human operators understand their potential and limitations becomes crucial.

Moreover, environmental concerns play a significant role in the automation journey. Mining companies face pressure to minimize their ecological footprint. Automation can enable more precise resource extraction and waste reduction. Yet, unless companies adopt sustainable practices, they risk public backlash and regulatory hurdles.

**Tips:** Focus on training teams to embrace new technologies. Monitor environmental impact metrics to stay accountable. Cultivating a culture of innovation can lead to better adoption of automation.