In today's rapidly evolving industrial landscape, the push for enhanced efficiency and productivity has propelled the adoption of advanced industry automation solutions. Experts in this field, such as Dr. Emily Johnson, a renowned authority on industrial automation, emphasize the transformative impact of these technologies. She states, "Embracing industry automation solutions not only streamlines operations but also positions companies to respond swiftly to market demands and improve their bottom line."

As organizations across various sectors seek to optimize their processes, implementing the right automation strategies becomes critical. Industry automation solutions offer a myriad of opportunities to reduce waste, enhance performance, and foster innovation. By automating repetitive tasks and integrating data-driven decision-making, businesses can unlock unprecedented levels of productivity. The potential for operational excellence is immense, as companies that invest in these solutions often find themselves at the forefront of industry advancements.

In exploring the top industry automation solutions available today, it becomes clear that the path to efficiency is paved with technology-driven approaches. Whether it’s through robotics, artificial intelligence, or smart manufacturing systems, understanding and leveraging these tools is essential for any organization aspiring to thrive in a competitive marketplace. As we delve into the specifics, we will uncover how these automation solutions not only enhance productivity but also pave the way for sustainable growth and innovation in various industries.

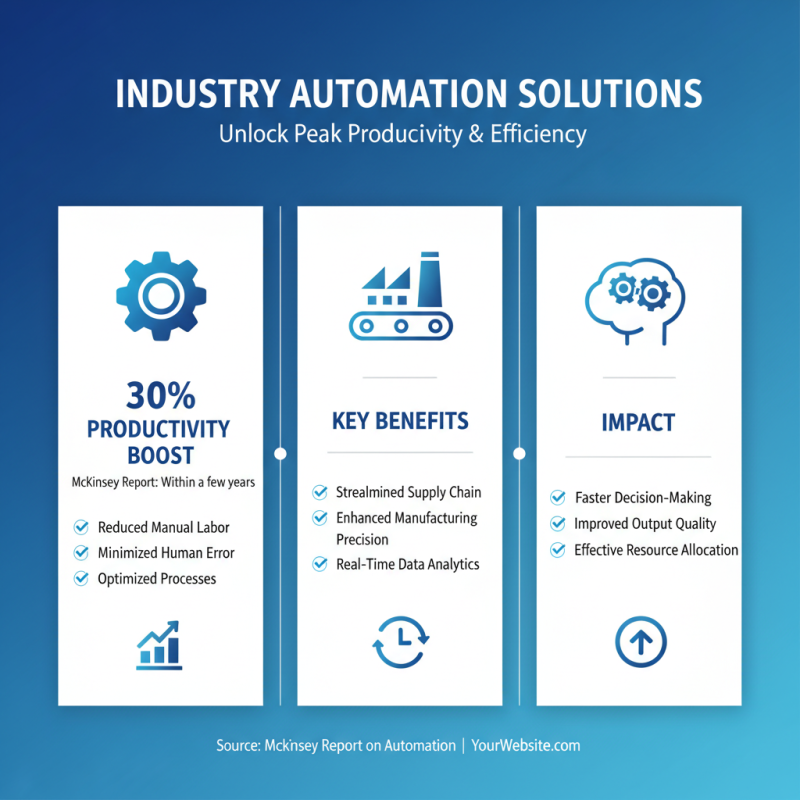

Industry automation solutions have become pivotal in enhancing operational efficiency and overall productivity across various sectors. According to a report by McKinsey, companies that implement automation technologies can improve productivity by as much as 30% within a few years. This surge can be attributed to reduced manual labor, minimized human error, and optimized processes, allowing businesses to allocate resources more effectively. Automated systems can streamline supply chain operations, enhance precision in manufacturing, and enable real-time data analytics, all of which contribute to faster decision-making and improved output quality.

To effectively implement these automation solutions, businesses should consider the specific needs of their operations. Tips for successful automation include starting small with pilot projects to assess the technology's impact before a full rollout. Additionally, regular employee training on new systems is crucial; a survey from Deloitte indicates that companies with strong training programs see productivity gains of over 20%. By fostering a culture of adaptability and continuous learning, organizations can ensure their workforce is equipped to leverage new technologies effectively, driving sustained innovation and growth.

The implementation of automation in various industries presents significant advantages

that can dramatically enhance both efficiency and productivity.

By streamlining repetitive tasks and reducing human error, automation allows organizations to allocate resources more effectively.

This not only leads to faster production cycles but also ensures a higher quality of output,

as machines often deliver consistent results without the variability that can occur with human labor.

Moreover, automation facilitates better data collection and analysis, enabling companies to make informed decisions in real-time.

With advanced integrated systems, businesses can monitor performance metrics, predict maintenance needs, and optimize supply chains more efficiently.

Employees are also freed from mundane tasks, allowing them to focus on more strategic initiatives

that can drive innovation and growth. Ultimately, the shift toward automation fosters a more agile and responsive organization,

well-equipped to meet the demands of an ever-changing market landscape.

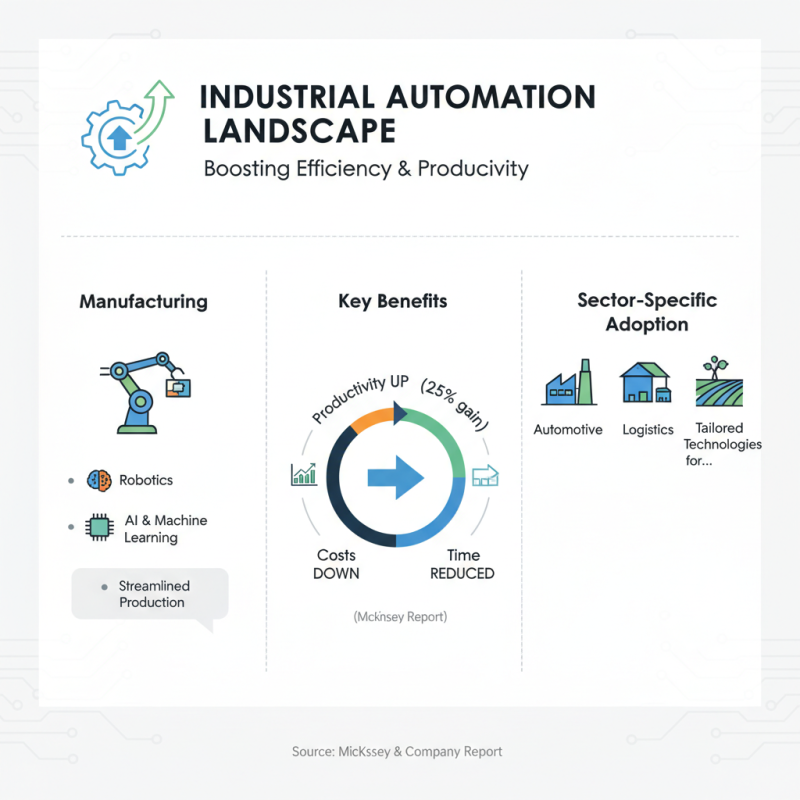

In today’s rapidly evolving industrial landscape, automation solutions play a crucial role in enhancing efficiency and productivity across various sectors. Different industries are adopting tailored automation technologies to meet their specific operational needs. For instance, the manufacturing sector is increasingly utilizing robotics and artificial intelligence (AI) to streamline production processes. According to a report by McKinsey, automation could boost productivity in manufacturing by up to 25%, significantly reducing costs and production times.

In the logistics and supply chain industry, automation solutions such as warehouse management systems and automated guided vehicles (AGVs) are becoming commonplace. These technologies help improve inventory accuracy and reduce order processing times. A study by PwC noted that automation in logistics could lead to a 30% reduction in operational costs, while simultaneously enhancing customer service through faster delivery times and real-time tracking capabilities. Similarly, the healthcare sector is embracing automation with electronic health records and robotic surgical systems, which not only minimize human errors but also enhance patient outcomes and operational efficiency. Research from the World Health Organization suggests that integrating automation in healthcare can lead to a productivity increase of up to 40% over the next decade.

By implementing these versatile automation solutions, industries can experience substantial improvements in both productivity and efficiency, driving long-term growth and innovation in their operations.

In today's rapidly evolving industrial landscape, automation has emerged as a pivotal strategy for businesses aiming to enhance efficiency and productivity. Several case studies illustrate the transformative potential of automation across various sectors. For instance, a manufacturing company implemented an automated inventory management system that streamlined their supply chain operations. This system not only reduced manual errors but also improved order fulfillment rates, leading to increased customer satisfaction and a notable rise in profit margins.

Another compelling case involves a logistics provider that adopted robotic process automation to optimize its shipping processes. By automating routine tasks such as order processing and shipment tracking, the company was able to significantly decrease turnaround times. Employees could then focus on more complex tasks requiring human oversight, thereby augmenting productivity.

The automation initiative led to enhanced operational efficiency and allowed the firm to handle a greater volume of shipments without scaling its workforce, showcasing the effectiveness of automation in driving business growth.

As industries continue to evolve, the trends in automation technology are becoming increasingly sophisticated, pushing the boundaries of efficiency and productivity. One of the most notable trends is the integration of artificial intelligence and machine learning into industrial processes. These technologies allow machines to learn from data and make real-time adjustments, leading to optimized workflows and minimized downtime. The capacity for predictive maintenance is significantly enhanced, enabling organizations to foresee equipment failures and address them proactively, thus saving both time and resources.

Additionally, the rise of IoT (Internet of Things) is transforming the landscape of automation in industries. By connecting various devices and machines, organizations can collect vast amounts of data, allowing for comprehensive analysis and improved decision-making. Real-time monitoring and control capability empower businesses to streamline operations, enhance product quality, and respond swiftly to market demands. This interconnected framework not only enhances operational visibility but also fosters a culture of continuous improvement, paving the way for a more agile and responsive manufacturing environment.

As these technologies continue to mature, industries will witness unprecedented advancements in productivity and efficiency, reshaping the future of work.