In the rapidly evolving landscape of Industry 4.0, pneumatic automation stands at the forefront of revolutionizing manufacturing efficiency. Experts in the field emphasize the transformative potential of integrating advanced pneumatic systems into production processes. According to Dr. Emily Sanchez, a renowned authority in pneumatic automation, "Harnessing the capabilities of pneumatic technology can dramatically enhance operational efficiency, reduce downtime, and drive innovation across sectors." This statement underlines the significance of pneumatic automation in optimizing workflows and boosting productivity.

As manufacturers seek to remain competitive in an increasingly automated world, the adoption of pneumatic solutions is more critical than ever. These systems not only improve the speed and precision of manufacturing operations, but they also contribute to sustainability by minimizing energy consumption and waste. In this context, we will explore the top five ways pneumatic automation is set to shape the future of manufacturing, demonstrating its pivotal role in achieving the goals of Industry 4.0.

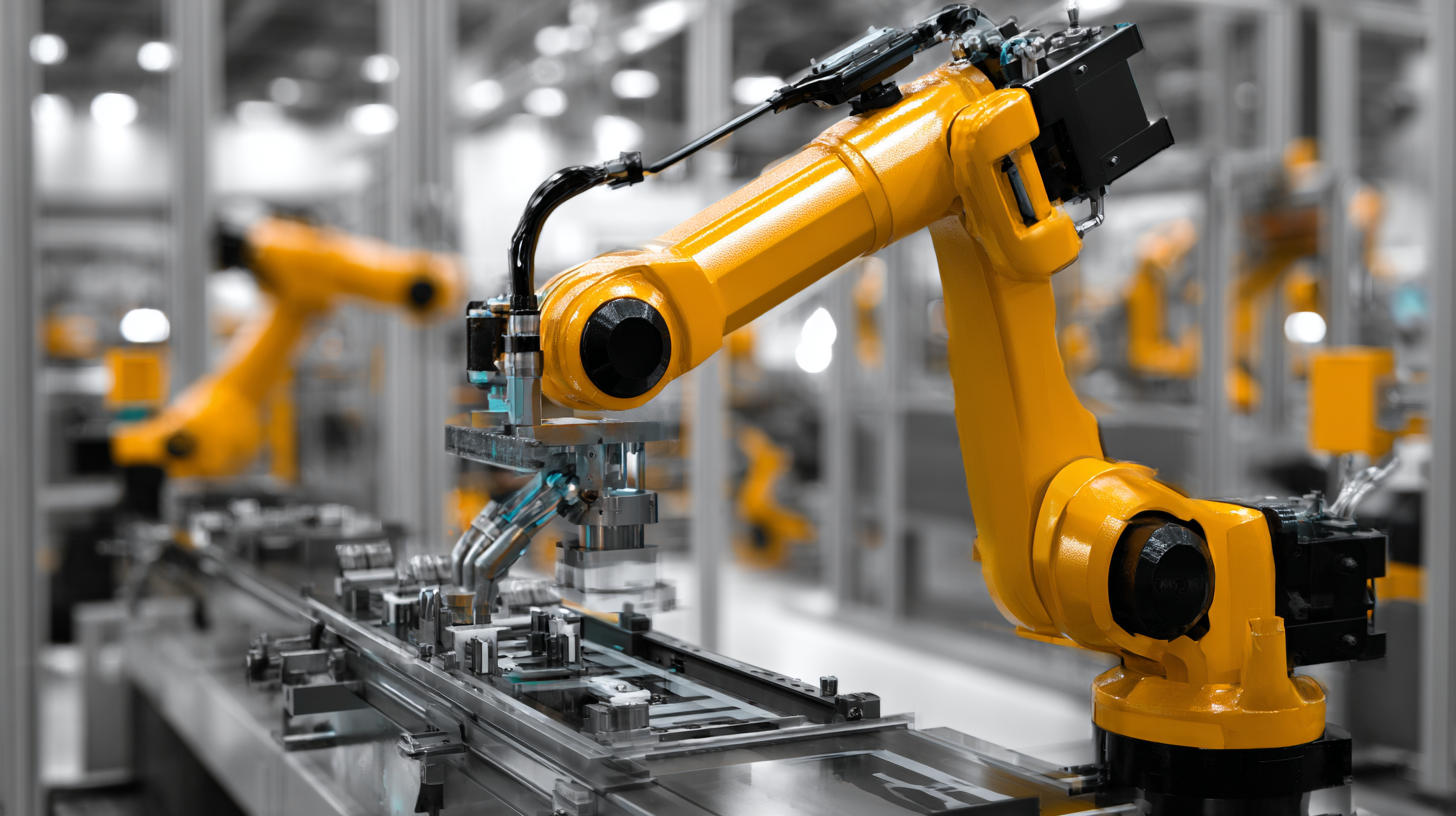

Pneumatic automation is poised to significantly enhance the manufacturing workflow efficiency in the context of Industry 4.0. By leveraging compressed air systems, manufacturers can achieve rapid and precise movements that streamline production processes. This technology allows for flexible configuration and easy reprogramming, which is essential in today's fast-paced market where product customization and quick turnaround times are paramount. As a result, manufacturers can reduce setup times and optimize machine utilization, leading to increased output without sacrificing quality.

Pneumatic automation is poised to significantly enhance the manufacturing workflow efficiency in the context of Industry 4.0. By leveraging compressed air systems, manufacturers can achieve rapid and precise movements that streamline production processes. This technology allows for flexible configuration and easy reprogramming, which is essential in today's fast-paced market where product customization and quick turnaround times are paramount. As a result, manufacturers can reduce setup times and optimize machine utilization, leading to increased output without sacrificing quality.

In addition to enhancing speed and versatility, pneumatic automation contributes to greater resource management. By employing advanced sensors and data-driven analytics, manufacturers can monitor performance in real time, identifying inefficiencies and areas for improvement. The integration of pneumatic systems with digital technologies facilitates smart manufacturing practices, leading to less downtime and more reliable operations. This holistic approach not only boosts productivity but also fosters a sustainable manufacturing environment by minimizing waste and energy consumption. As industries continue to evolve, the role of pneumatic automation in driving workflow efficiency will become increasingly vital, setting the foundation for a more agile and responsive manufacturing landscape.

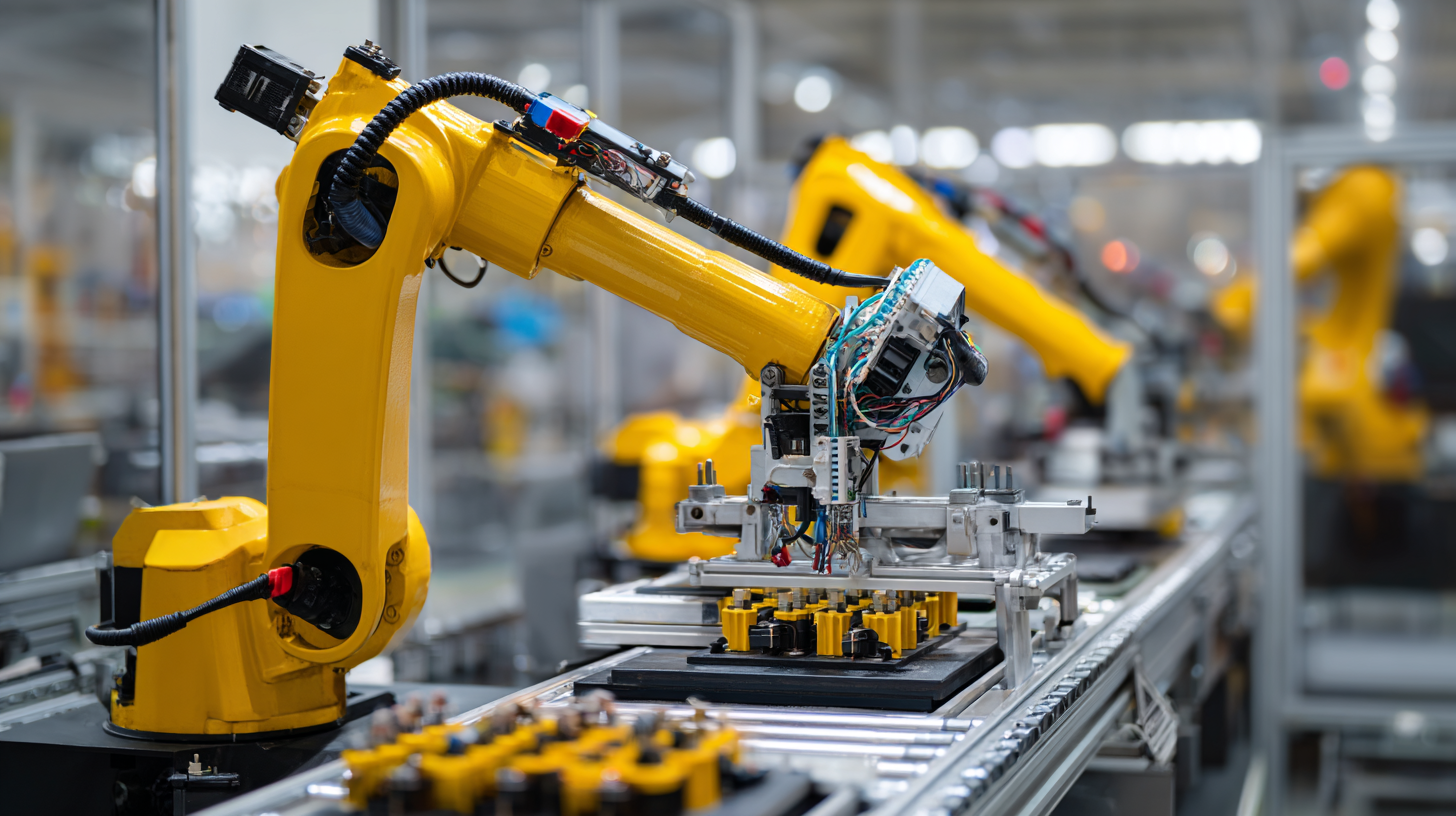

As Industry 4.0 reshapes the manufacturing landscape, pneumatic automation emerges as a key player in enhancing operational efficiency. The integration of smart technologies with pneumatic systems is revolutionizing how industries operate. Innovations such as IoT-enabled pneumatic valves and advanced air treatment components are paving the way for more responsive and adaptive manufacturing processes. These advancements not only improve manufacturing efficiency but also reduce energy consumption, making them crucial for sustainability.

Tips: Consider implementing IoT sensors in your pneumatic systems to monitor performance in real-time. This can lead to proactive maintenance, minimizing downtime and extending the lifespan of your equipment.

Moreover, the development of smart actuators and valves equipped with AI algorithms allows for better precision and automation, contributing to optimized workflows and reduced cycle times. As the pneumatic components market continues to expand, businesses must stay ahead of these trends to leverage the full potential of their automation strategies.

Tips: Regularly review and assess the latest innovations in pneumatic technology to identify opportunities for upgrading your systems. Such proactive measures can significantly enhance production capabilities and competitive edge in the market.

The integration of the Internet of Things (IoT) with pneumatic systems is set to redefine manufacturing performance in the context of Industry 4.0. By incorporating IoT into pneumatic automation, manufacturers can achieve real-time monitoring and control over their operations. This connectivity allows for greater visibility into system performance, enabling prompt diagnostics and predictive maintenance. As sensors gather critical data on pressure, flow rates, and other operational metrics, manufacturers can optimize their processes and reduce downtime, significantly enhancing overall efficiency.

Furthermore, the IoT facilitates the seamless exchange of information across various systems and devices within a manufacturing environment. Pneumatic systems equipped with smart sensors can communicate with other assets, data analytics platforms, and even operators in real time. This ability not only streamlines workflows but also enhances decision-making processes by providing actionable insights. As organizations embrace these advanced technologies, the potential for increased productivity and cost savings becomes more pronounced, marking a transformative shift in the manufacturing landscape.

In the era of Industry 4.0, pneumatic automation is emerging as a key player in driving sustainability and cost savings in manufacturing processes. By utilizing compressed air for powering machinery and tools, pneumatic systems offer a cleaner alternative to traditional methods that heavily rely on electricity and fossil fuels. This shift not only reduces carbon footprints but also aligns with the growing demand for eco-friendly manufacturing practices. As industries increasingly adopt these systems, they can minimize waste and enhance energy efficiency, contributing significantly to a sustainable future.

Moreover, the integration of pneumatic automation leads to cost savings that cannot be overlooked. The simplicity of pneumatic systems often results in lower installation and maintenance costs compared to electric counterparts. Their durability and less complex nature mean reduced downtime and fewer repairs, which translates into significant long-term savings. As manufacturers seek to optimize their operations, pneumatic automation offers a compelling solution that balances economic viability with environmental responsibility, making it a vital component in the modern industrial landscape.

This chart illustrates the projected cost savings and sustainability benefits of implementing pneumatic automation across various industries by 2025.

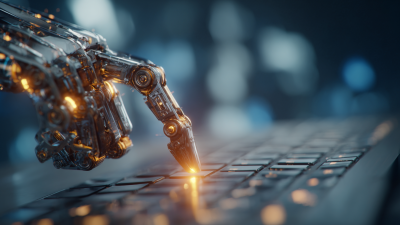

The rapid advancement of artificial intelligence (AI) is set to redefine pneumatic automation, especially within the context of Industry 4.0. By integrating AI algorithms with pneumatic systems, industries can harness data-driven insights for enhanced efficiency and decision-making. AI can analyze operational data in real-time, predict failures, and optimize maintenance schedules, resulting in reduced downtimes and increased production reliability. For instance, smart sensors could alert operators to deviations in system performance, enabling proactive adjustments to maintain optimal functioning.

**Tips:** To maximize the benefits of AI in pneumatic automation, industries should consider investing in training for their workforce. Understanding AI tools and data analysis will empower employees to leverage these technologies effectively. Additionally, companies should adopt a phased approach to implementation, starting with pilot projects that allow gradual integration and fine-tuning of AI solutions.

Furthermore, the emergence of machine learning techniques allows these systems to evolve continuously, adapting to new challenges and production environments. This not only boosts operational efficiency but also encourages innovation in creating more sustainable and flexible manufacturing processes. By embracing the synergy between AI and pneumatic automation, businesses can position themselves at the forefront of the manufacturing revolution.

**Tips:** Regularly update your technology stack to stay abreast of the latest AI developments. Partnering with tech firms specializing in AI can also foster innovation and provide access to cutting-edge solutions tailored for pneumatic applications.