The automation industry is evolving rapidly. As we explore the top 10 innovations, we recognize their profound impact. Dr. Sarah Chen, a renowned expert in automation, once said, “Innovations are reshaping how we work and live.” Her insight captures the essence of today’s developments.

New technologies in this sector include AI-driven robotics and smart sensors. These advancements streamline processes and improve efficiency. However, not every innovation is flawless. Some technologies face resistance from workers worried about job loss. Balancing automation and human involvement remains a complex challenge.

The automation industry must also address ethical considerations. For instance, data privacy issues arise with increased automation. Stakeholders must ensure these innovations benefit society while minimizing risks. Engaging in thoughtful discussions is essential to navigate this evolving landscape effectively.

Automation has transformed industries profoundly. By replacing manual tasks with automated processes, companies can increase efficiency and reduce costs. According to a recent report by McKinsey, automation can increase productivity by up to 20-30% in certain sectors. This represents a significant efficiency gain.

The rise of artificial intelligence and machine learning has also contributed to automating complex decision-making processes. A study by Deloitte highlights that 53% of organizations have adopted some form of automation. However, this isn't without challenges. Many companies struggle with integrating new technologies seamlessly into existing workflows. There are concerns about job displacement, as automation increasingly takes over routine tasks.

Moreover, automation can lead to a reliance on technology that may impact human oversight. The balance between efficiency and quality control remains contentious. Reports suggest that up to 30% of automation projects fail to deliver the expected results, primarily due to unclear objectives. Addressing these issues is crucial for businesses looking to harness the full potential of automation.

| Innovation | Description | Impact | Year Introduced |

|---|---|---|---|

| Robotic Process Automation (RPA) | Automation of repetitive tasks using software robots. | Increased efficiency and reduced operational costs. | 2012 |

| Artificial Intelligence in Automation | Integration of AI to enhance decision-making processes. | Improved accuracy and predictive analytics. | 2016 |

| Internet of Things (IoT) in Automation | Connecting devices for real-time monitoring and control. | Enhanced data collection and operational oversight. | 2015 |

| Cloud Robotics | Using cloud computing for robot intelligence and data storage. | Scalability and improved collaboration between robots. | 2013 |

| Collaborative Robots (Cobots) | Robots designed to work alongside humans safely. | Enhanced productivity and worker safety. | 2015 |

| Automated Quality Control | Using automation tools to monitor quality processes. | Reduction in defects and waste. | 2017 |

| Digital Twins | Creating a virtual model of a physical asset. | Real-time performance monitoring and predictive maintenance. | 2018 |

| Predictive Maintenance | Using analytics to predict equipment failures. | Reduced downtime and maintenance costs. | 2014 |

| Autonomous Vehicles | Vehicles that can drive themselves without human intervention. | Revolutionizing transport and logistics. | 2019 |

The automation industry is rapidly evolving, driven by exciting technologies. Robotics has transformed manufacturing. Robots work alongside humans, taking on repetitive tasks. This reduces errors and increases efficiency. However, the integration process can be complex. Companies often face difficulties adapting to new robotic systems.

Artificial intelligence has become a game-changer. AI can analyze vast amounts of data, making real-time decisions. It improves predictive maintenance in machinery. Yet, AI's reliance on data can lead to biased outcomes. Companies must ensure diversity in data sets for fair results.

Another key technology is the Internet of Things (IoT). IoT creates connected devices that communicate seamlessly. Smart sensors provide real-time insights into operations. This visibility helps in optimizing workflows. Still, with increased connectivity comes cybersecurity risks. Organizations need robust security measures to protect sensitive information. Balancing innovation with security is a challenge that remains.

Manufacturing automation is undergoing a transformative overhaul. Industry experts predict that by 2025, 85 million jobs will be replaced by automation, while 97 million new roles will emerge. This shift highlights the critical innovations reshaping how we approach manufacturing. Robotics, artificial intelligence, and IoT devices are at the forefront of this change.

Data from a recent survey reveals that 66% of companies are investing heavily in automation technologies. These innovations enhance efficiency and reduce human error. For instance, smart sensors can monitor machinery in real-time, alerting operators of potential failures before they happen. This predictive maintenance can reduce downtime by as much as 30%.

Tips: Evaluate your current automation strategies. Are your processes up to date? Keep an eye on industry trends. Continuous improvement is vital. Another important aspect is employee training. Workers must embrace technology to thrive in this evolving landscape. The inconsistency in adapting to these innovations can lead to missed opportunities and potential disruptions. Assess whether your workforce is ready to adopt these tools.

A notable innovation is the use of collaborative robots, or cobots. They work alongside humans, increasing productivity without replacing jobs. Around 40% of firms report higher efficiency when integrating cobots into their workflows. However, there's a need for caution. Over-reliance on automation may lead to a workforce that lacks essential hands-on skills. Balancing technology with human expertise remains a pressing challenge.

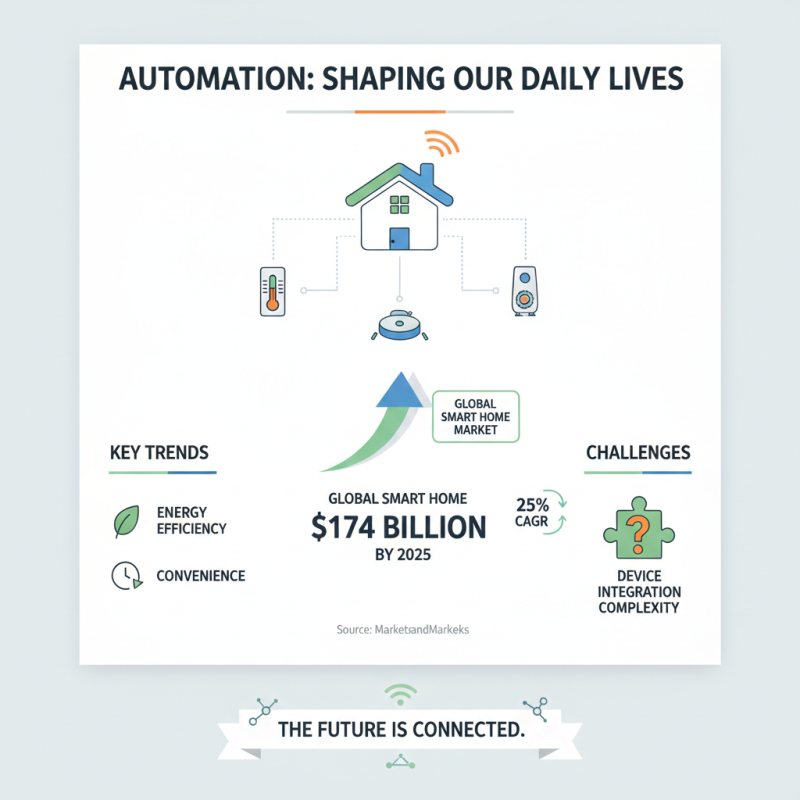

Automation is shaping our daily lives in significant ways. From smart thermostats to robotic vacuum cleaners, automation technologies are becoming commonplace. According to a report by MarketsandMarkets, the global smart home market is projected to reach $174 billion by 2025, growing at a CAGR of 25%. This shift is driven by the need for convenience and energy efficiency. Yet, there are challenges. Many users struggle with the complexity of integrating multiple devices.

Smart home systems can enhance security and efficiency. For instance, automated lighting can reduce energy waste while providing safety. However, data privacy remains a concern. A study by KPMG found that 86% of consumers are worried about data breaches in smart home devices. Users often overlook these risks while enjoying the conveniences of automation.

Moreover, while automation brings numerous benefits, not everyone fully understands its capabilities. A report from Adobe revealed that roughly 60% of users have not explored all features of their smart home devices. This highlights a gap in knowledge. As automation continues to evolve, awareness and education need to keep pace to maximize its potential.

The automation industry is rapidly evolving. According to a recent report by McKinsey, automation could raise productivity by 1.4% each year. This trend signifies a shift in how businesses operate. Many companies are already embracing robotic process automation (RPA). It allows for repetitive tasks to be conducted by machines. However, not all organizations have adapted evenly. Some struggle with integration and workforce training.

AI and machine learning play a crucial role in shaping the future of automation. A study from Gartner predicts that by 2025, 75% of organizations will have invested in some form of AI. This integration enhances decision-making processes. Yet, there are concerns about job displacement. Many employees fear that automation will replace them entirely. Addressing these fears must be a priority for businesses.

Furthermore, the Internet of Things (IoT) is becoming vital in automation. Data from Statista shows that there will be over 30 billion connected devices by 2025. These devices help gather real-time data, improving efficiency. However, cybersecurity risks also increase. Companies need to invest in security measures to protect sensitive information. This balance between innovation and safety will define the industry's path forward.

This chart illustrates the top innovations in the automation industry based on their estimated impact on efficiency improvement. The data reflects trends toward increased automation across various sectors.