In today's rapidly evolving manufacturing landscape, the importance of "automation for industry" cannot be overstated. As businesses strive to enhance efficiency, reduce costs, and maintain competitiveness, the integration of automated systems has emerged as a pivotal factor in achieving success. Leading expert in industrial automation, Dr. Nina Patel, emphasizes this urgency, stating, "Automation for industry is not just an option; it's a necessity for any manufacturer aiming to thrive in the modern marketplace."

The shift toward automation represents a transformative leap in how industries operate, enabling organizations to streamline processes, optimize resource allocation, and improve overall productivity. With the advent of advanced technologies such as artificial intelligence and the Internet of Things, "automation for industry" is redefining not only production capabilities but also the future of workforce dynamics. As manufacturers embrace these innovations, they are positioned not only to respond to current demands but also to anticipate and adapt to future challenges in their respective sectors.

In this context, understanding the critical role of automation in fostering innovation and sustainability will be crucial for industry leaders. As we delve into the nuances of why automation for industry is essential for modern manufacturing success, it becomes evident that embracing these changes is vital for ensuring long-term viability and growth.

Automation has become a cornerstone of modern manufacturing, significantly enhancing efficiency across various processes. By integrating automated systems, manufacturers can streamline operations, minimize human error, and achieve higher output rates. Automation facilitates the rapid execution of repetitive tasks, allowing human workers to focus on more complex and strategic responsibilities. This shift not only boosts productivity but also fosters innovation, as companies can allocate resources toward research and development while machines handle the routine.

Furthermore, automation contributes to improved quality control within manufacturing processes. Advanced technology, such as robotics and artificial intelligence, enables precise manufacturing operations with consistent quality standards. By employing automated inspection systems, manufacturers can detect defects in real-time, reducing waste and ensuring that only high-quality products reach the market. This not only enhances customer satisfaction but also builds trust in the manufacturing brand, as consumers increasingly expect reliability and excellence in the products they purchase. Overall, automation stands as a vital component in the pursuit of manufacturing efficiency, driving success in an ever-competitive industry landscape.

The landscape of modern manufacturing is being dramatically reshaped by several key automation technologies. One of the most significant drivers is the implementation of robotics, which enhances efficiency and precision on the production line. Automated robots can perform repetitive and complex tasks with a speed and accuracy that far surpasses human capabilities. This not only leads to increased output but also reduces the likelihood of errors, thereby improving overall product quality.

Another pivotal technology in the realm of automation is the integration of the Internet of Things (IoT). IoT devices facilitate real-time monitoring and data collection throughout the manufacturing process, enabling manufacturers to optimize their operations. By harnessing data analytics and machine learning, companies can predict maintenance needs to prevent downtime and make informed decisions regarding resource allocation. This interconnectedness not only streamlines workflows but also enhances responsiveness to market changes, ensuring that manufacturers remain competitive in a rapidly evolving industry.

Moreover, advancements in artificial intelligence (AI) profoundly influence automation by driving smarter decision-making processes. AI technologies enable predictive analytics, allowing manufacturers to anticipate trends and adjust production schedules accordingly. This agile approach to manufacturing fosters innovation and flexibility, essential for thriving in today’s dynamic market environment. Collectively, these technologies not only enhance operational efficiency but also lay the foundation for sustainable growth in modern manufacturing.

Automation in the manufacturing sector fundamentally alters the landscape of workforce dynamics and skills requirements. As industries embrace advanced technologies such as robotics, artificial intelligence, and machine learning, the demand for a highly skilled workforce is more pronounced than ever. Traditional manufacturing roles that relied on manual labor are increasingly being replaced by positions that require operators to manage and maintain automation systems. This shift necessitates a reevaluation of training programs and educational pathways to ensure that workers possess the technical proficiencies required to thrive in a technologically advanced environment.

Moreover, the integration of automation transforms job roles, often leading to the emergence of hybrid positions that combine operational expertise with technology-driven capabilities. For instance, employees are now expected to not only oversee automated equipment but also analyze data and implement process improvements based on insights drawn from these sophisticated systems. Consequently, companies must invest in continuous learning opportunities and reskilling initiatives to equip their workforce with relevant knowledge in data analytics, programming, and system maintenance. This evolution fosters a culture of adaptability and innovation, enabling workers to contribute effectively to their organizations while preparing them for future career advancements.

Successful automation implementations in industry demonstrate the profound impact of technology on modern manufacturing. One notable case study involves a mid-sized automotive parts manufacturer that adopted automated robotic arms on its assembly line. This led to a 30% increase in productivity while minimizing the risk of human error. The company also reported a significant reduction in labor costs, allowing them to reallocate resources towards innovation and product development. Such real-world applications highlight how automation can streamline processes and enhance efficiency across the manufacturing sector.

When considering automation, it’s essential to assess the specific needs of your operation. One tip is to start small with pilot projects; this allows you to gauge the effectiveness of automation without overwhelming your processes. Another important suggestion is to involve your workforce during the planning phases. Empowering employees to provide input can lead to solutions that are more tailored to your unique environment, ultimately increasing buy-in and reducing resistance to change.

In a different example, a food processing plant integrated automated packaging systems that not only expedited production but also improved product quality through consistent and precise packaging. The system allowed for real-time monitoring, enabling the company to quickly address any potential issues. Such implementations emphasize the importance of ongoing assessment and adaptation in automation strategies, ensuring sustained success in the ever-evolving landscape of manufacturing.

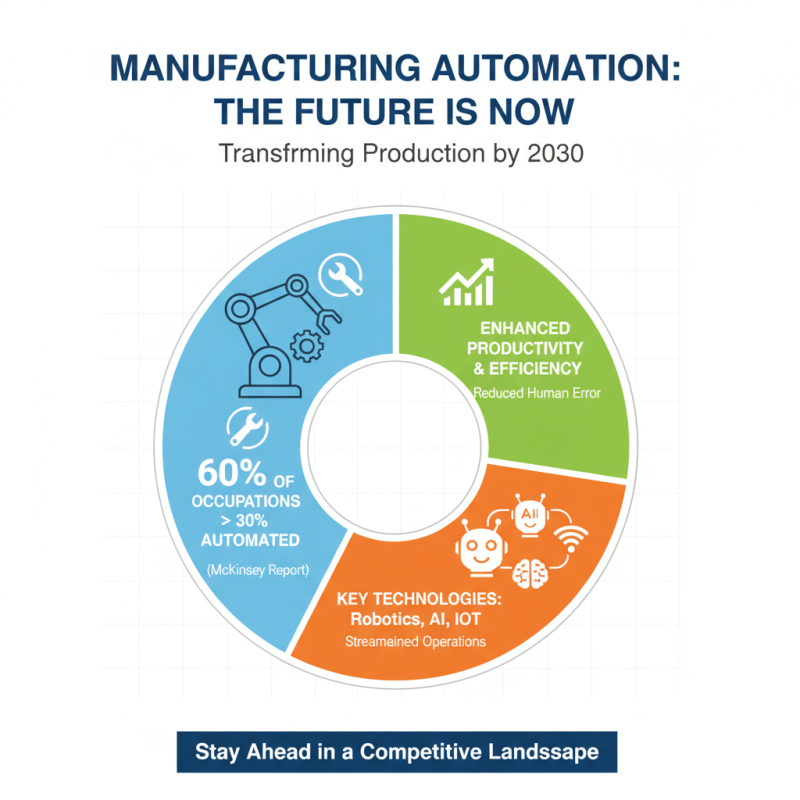

Automation is rapidly transforming manufacturing processes, and its evolution is crucial for staying ahead in a competitive landscape. According to a report by McKinsey, nearly 60% of all occupations in manufacturing could have at least 30% of their activities automated by 2030. This shift will significantly enhance productivity, reduce human error, and allow for unprecedented levels of efficiency in production lines. As technologies like robotics, artificial intelligence, and the Internet of Things (IoT) become more integrated into manufacturing, companies can streamline operations and respond agilely to market demands.

Looking ahead, the industry is poised to see advancements in collaborative robots (cobots) that work alongside humans to increase output and safety. A study by the International Federation of Robotics projects that the global market for industrial robots could reach over 1.5 million units by 2025, marking a significant leap in technological adoption. Furthermore, predictive maintenance driven by AI will help manufacturers minimize downtime by up to 20%, as machines will increasingly be able to self-diagnose issues before they lead to failures. These trends illustrate that as automation evolves, it not only drives efficiency but also sets the foundation for innovative manufacturing strategies that cater to an ever-changing market.