In today's fast-paced industrial landscape, the integration of automation equipment has emerged as a game-changer for manufacturers seeking efficiency and innovation. The rapid advancements in automation technology are not only transforming traditional manufacturing processes but also reshaping entire supply chains and operational strategies. With the ability to enhance precision, reduce human error, and optimize productivity, automation equipment is becoming an indispensable element in modern factories.

As manufacturers face increasing pressure to meet consumer demands while controlling costs, the implementation of automation in production lines is no longer a luxury but a necessity. This shift is evident in the rise of smart factories where interconnected machinery operates seamlessly, driven by sophisticated algorithms and real-time data analytics. The impact of automation equipment extends beyond simple tasks; it is revolutionizing how products are conceptualized, produced, and delivered to the market.

In this article, we will explore the "Top 5" ways automation equipment is transforming manufacturing processes. From improving workflow efficiency to enabling mass customization, these advancements are setting new standards for speed and quality in production, ultimately paving the way for the future of manufacturing.

The role of automation in modern manufacturing cannot be overstated. With the integration of advanced technologies such as robotics, artificial intelligence, and machine learning, manufacturers are experiencing a substantial transformation in their production processes. Automation allows for higher efficiency, reduced production times, and increased accuracy, which are critical in meeting the demands of today's fast-paced market. By leveraging these technologies, companies can minimize human error and optimize resource management, leading to better overall productivity.

Tips for implementing automation effectively include starting with a thorough analysis of current processes to identify bottlenecks and areas for improvement. It's vital to engage employees in the transition, as their insights can lead to more effective integration of automation technologies. Another key tip is to invest in training and development programs, ensuring that the workforce is well-equipped to work alongside automated systems. This not only increases acceptance of new technologies but also enhances overall operational efficiency.

In addition, manufacturers should consider adopting a phased approach to automation. Rather than overhauling entire systems at once, introducing automation incrementally allows for adjustments based on feedback and outcomes, reducing the risk associated with large-scale changes. As companies embrace this shift, the focus remains on combining human ingenuity with machine efficiency for a future of smarter manufacturing.

Automation in modern manufacturing is increasingly driven by advanced technologies such as digital twins. This innovative approach allows for enhanced simulation designs and high-resolution modeling, making precise manufacturing processes more attainable. By leveraging digital twin technology, manufacturers can create accurate replicas of products and processes that facilitate real-time monitoring and optimization, thereby accelerating innovation in product design and overall efficiency.

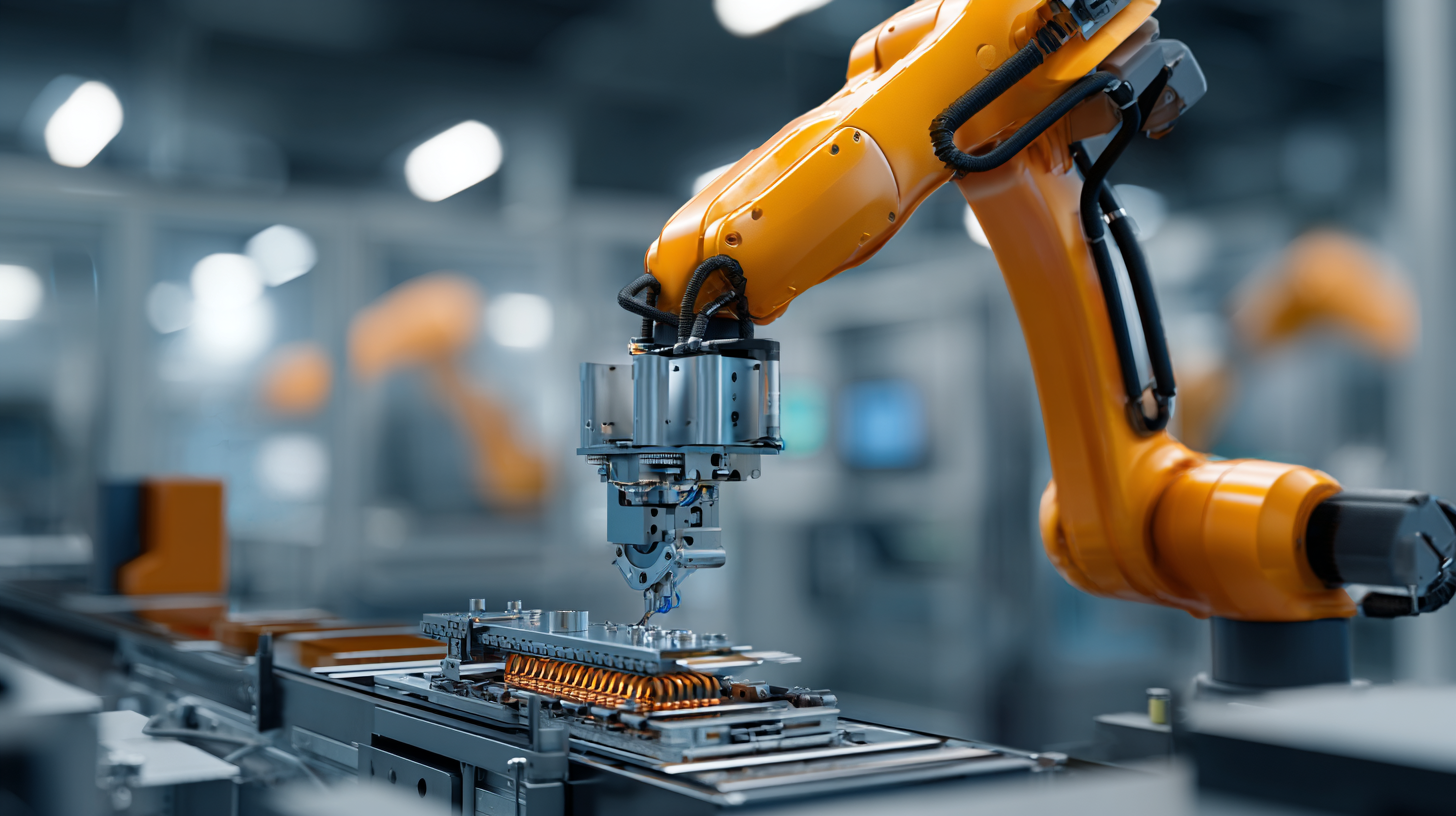

Moreover, initiatives like the "National Intelligent Manufacturing Standard System Construction Guide (2024 Edition)" play a crucial role in advancing the standardization of smart manufacturing practices. By focusing on a top-level design that emphasizes standards, this initiative aims to guide the high-quality development of intelligent manufacturing. Companies are encouraged to persist in innovation and pursue domestic alternatives, further solidifying the framework necessary for deploying automation technologies across the industry. Events such as the World Intelligent Manufacturing Conference showcase this commitment, bringing together global participants to explore the integration of digital and physical manufacturing systems, with hundreds of industrial robots demonstrating the potential of automation in transforming production processes.

| Technology | Description | Benefits | Applications |

|---|---|---|---|

| Robotics | Use of robots to automate tasks in manufacturing. | Increased precision, reduced labor costs, and enhanced safety. | Assembly lines, packaging, and material handling. |

| IoT (Internet of Things) | Network of interconnected devices to collect and exchange data. | Real-time monitoring, efficient maintenance, and improved decision-making. | Supply chain management, predictive maintenance, and smart factories. |

| Artificial Intelligence | Machine learning and algorithms to optimize processes. | Enhanced efficiency, reduced downtime, and improved quality control. | Quality assurance, demand forecasting, and process automation. |

| 3D Printing | Additive manufacturing technology for producing parts. | Reduced waste, faster prototyping, and complex designs. | Prototype development, custom components, and small batch production. |

| Cloud Computing | Remote servers for data storage and processing. | Scalability, cost-effectiveness, and easy data access. | Data analytics, collaboration tools, and virtual simulations. |

The implementation of automation equipment in modern manufacturing processes has transformed the industry, yielding significant benefits that are hard to overlook. According to a report by McKinsey, companies that automate their production lines can expect to see productivity improvements of up to 30%. This surge in efficiency not only accelerates production rates but also helps in reducing operational costs, allowing manufacturers to reallocate resources and invest in innovation.

Moreover, automation equipment enhances quality control, minimizing human errors which can lead to costly defects. A study from Deloitte reveals that manufacturers adopting automated systems have experienced a reduction in defect rates by approximately 50%. This not only fosters customer satisfaction but also strengthens the brand's reputation in a competitive market. By integrating advanced technologies such as robotics and artificial intelligence, businesses can achieve precision and consistency in their products, establishing a robust foundation for sustained growth and success in today's fast-paced manufacturing landscape.

The adoption of automation technologies in modern manufacturing presents a myriad of challenges that companies must navigate to fully reap the benefits. One significant hurdle is the initial capital investment required for advanced automation equipment and systems. Many businesses, particularly small to medium-sized enterprises (SMEs), may struggle to allocate insufficient resources for these technologies. To overcome this, manufacturers can explore financing options, government incentives, and partnerships that can assist in sharing costs while gradually integrating automation into their processes.

Additionally, the integration of automation often requires a cultural shift within organizations. Employees may resist changes due to fears of job loss or the need to learn new skills. Addressing this challenge involves transparent communication about the role of automation in enhancing productivity rather than replacing human workers. Implementing comprehensive training programs can also empower employees, equipping them with the necessary skills to collaborate effectively with automated systems. By fostering a culture that embraces technological advancements, manufacturers can facilitate smoother transitions and ensure that automation is seen as a tool for growth and innovation.

The landscape of manufacturing is undergoing a transformative shift as automation equipment continues to evolve. Future trends indicate a significant move towards integrated smart manufacturing systems, where machines are interconnected and can communicate seamlessly. This integration opens the door for real-time data analysis, allowing manufacturers to optimize operations and reduce downtime. By utilizing the Internet of Things (IoT), manufacturers can monitor machinery performance continuously, predicting maintenance needs and minimizing disruptions to production.

In addition to connectivity, there is a growing emphasis on artificial intelligence (AI) and machine learning. These technologies empower machines to learn from their environments, improving efficiency and productivity. AI-driven robotics can adapt to changing tasks without requiring extensive reprogramming, making them highly versatile. As industries aim to become more sustainable, automation solutions are expected to incorporate eco-friendly practices, using less energy and minimizing waste. The future of automation in manufacturing not only enhances operational capabilities but also prioritizes sustainability, paving the way for smarter and greener production methods.